PRODUCTION PROCESS

At DZX Apparel, we follow a meticulously structured production workflow to ensure quality, efficiency, and transparency at every stage. Here’s how we transform your designs into finished products:

DESIGN & QUOTATION

At DZX APPAREL, we offer end-to-end design and transparent pricing solutions to bring your clothing ideas to life with creativity and precision.

Design Services

Our expert team delivers:

Custom Designs – From concept sketches to samples, tailored to your brand’s vision.

Trend-Driven Solutions – Market-relevant styles with fabric & trim recommendations.

Tech Packs & Prototyping – Clear specs for seamless production.

Competitive Quotation

We provide fast, detailed, and cost-effective pricing:

Breakdown Included – Fabric, labor, logistics, and MOQ flexibility.

Volume Discounts – Optimized pricing for small batches or bulk orders.

To ensure perfect fit across all sizes, our expert pattern makers will:

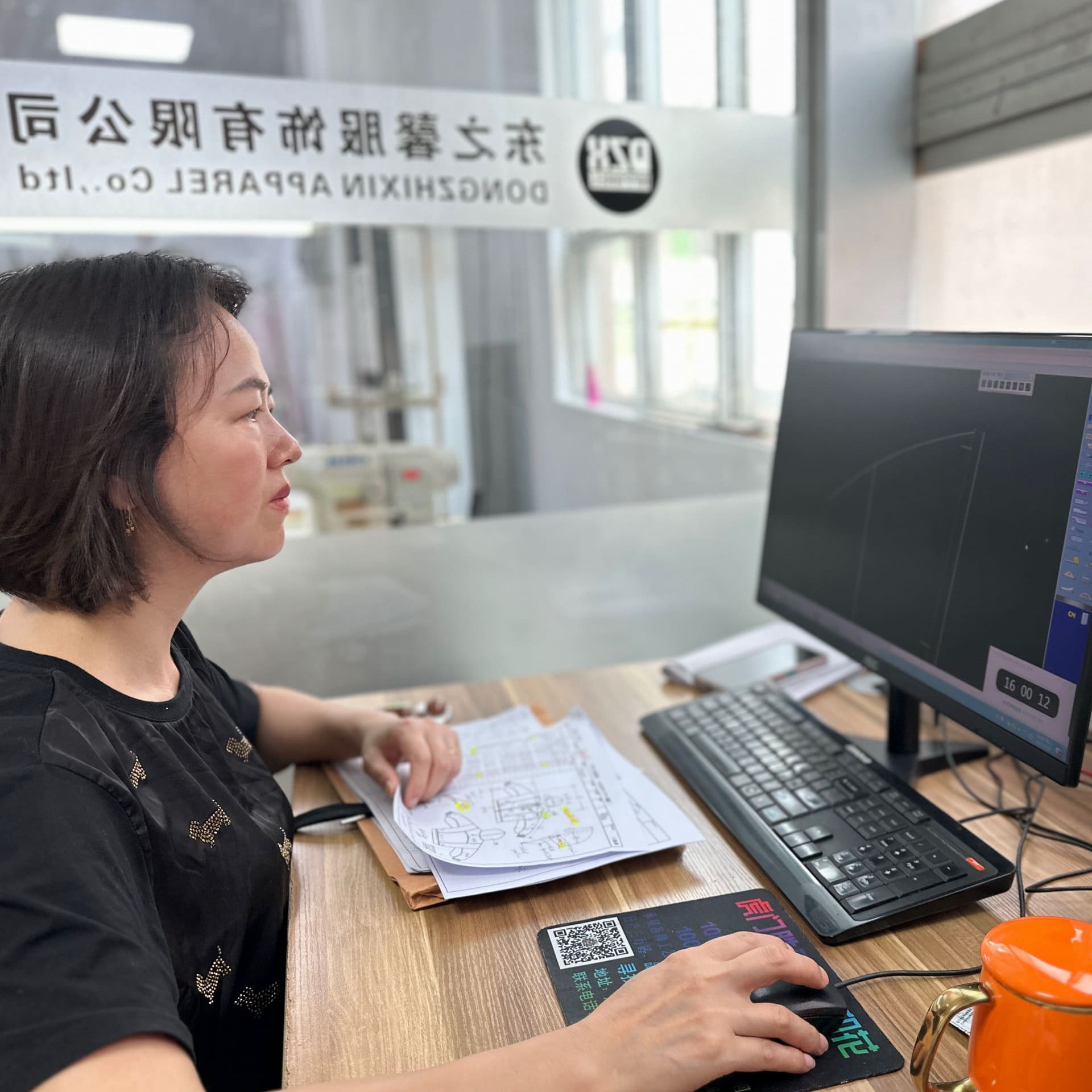

PATTERN CREATION

1.Create Precision Base Patterns

Develop technical patterns from your approved final measurements

Incorporate all design details, seam allowances, and construction methods

2.Full-Size Grading

Systematically scale patterns for each size in your range (XS-XXL or custom sizes)

Maintain proper proportions and design integrity across all sizes

3.Fit Optimization

Adjust patterns based on your specific fit standards

Accommodate different body types if required

4.Digital & Physical Patterns

Provide both digital patterns (for high-tech manufacturing) and traditional paper patterns (as needed)

To ensure perfect fit across all sizes, our expert pattern makers will:

PATTERN CREATION

1.Create Precision Base Patterns

Develop technical patterns from your approved final measurements

Incorporate all design details, seam allowances, and construction methods

2.Full-Size Grading

Systematically scale patterns for each size in your range (XS-XXL or custom sizes)

Maintain proper proportions and design integrity across all sizes

3.Fit Optimization

Adjust patterns based on your specific fit standards

Accommodate different body types if required

4.Digital & Physical Patterns

Provide both digital patterns (for high-tech manufacturing) and traditional paper patterns (as needed)

To guarantee your complete satisfaction before bulk production, we follow a meticulous sample approval system:

SAMPLING

1. Our Sample Guarantee

Every sample includes:

✔ 100% accurate sizing based on your tech pack

✔ Exact specified fabrics & trims

✔ Your branding elements (labels, tags, embroidery, etc.)

✔ Professional finishing matching bulk production quality

2. Purpose-Built Sampling

We provide:

Prototype samples for design confirmation

Fit samples for sizing approval

Pre-production samples as final reference

3. Approval Process

You’ll receive the sample within 7~10 days

Comprehensive evaluation period

Unlimited revisions until perfect

To guarantee your complete satisfaction before bulk production, we follow a meticulous sample approval system:

PRODUCTION

1.Fabric Cutting

After the fabric arrives and the patterns have been created and checked we will cut the fabrics for each panel.

2.Stitching

All panels will be stitched together to complete the garment construction.

- Garment Finishing

The garments will then be pressed, and any tags such as hang tags, will be added at this stage.

To deliver products that meet the highest international standards, we implement a rigorous two-tier inspection process:

QUALITY CONTROL

- In-House QC (First Defense)

Our factory quality team conducts:

✓ Stitch-per-inch verification

✓ Size measurement audits (+/- 1mm precision)

✓ Fabric integrity checks

✓ Trim attachment strength tests

✓ Functionality validation (zippers, buttons, etc.)

- Independent Third-Party Inspection (Final Gatekeeper)

We engage [Name of Accredited Inspection Company] to perform: